You cannot underestimate the importance of a Variable frequency inverter when it comes to optimum energy utilization. Most people who don’t use a variable frequency inverter face frequent motor repairs or damages. This is true regarding fluctuating load applications or higher speed requirement applications.

But you don’t need to worry when you have a variable frequency inverter. It will help you fulfilling variable frequency demands on the go. This article will discuss each aspect of the variable frequency inverter for which you are eager. Let’s uncover facts about this incredible piece of device.

What Do You Mean By Variable Frequency Inverter?

Variable frequency inverter refers to the device you can use to control the Torque or speed of your electric motor.

It does this by adjusting the voltage or frequency of the power supply. You can also enjoy control over ramping up and ramping down your motor. This is true, especially when you are practicing the start r stop of your motor.

Working Principle

The variable frequency inverter works by placing it between the power supply and the motor. The frequency and AC voltage then enter in the variable frequency inverter. The rectifier bridge, from there, transforms this voltage into DC voltage.

The DC then gets filtered by passing through the inductors and capacitors bank. Later it again converts the DC voltage back to AC voltage. This AC voltage in the ends then moves to the motor at the frequency level you need.

Main Components of the Variable Frequency Inverter

Three main components contribute to the effective functioning of your Variable frequency inverter. These components include:

- Converter

- DC Bus

- Inverter

The converter’s role is to convert the AC voltage into DC voltage. It acts as a rectifier. In case the voltage it receives differs from the voltage it sends to the motor. Then the converter first steps down or up the voltage to the appropriate level.

The role of the DC Bus is to filter or screen the voltage up to a proper voltage level. The dual role of this component is to transfer the DC voltage to the inverter.

In the end, comes the inverter. The role of the inverter is to convert DC voltage to AC voltage. It also plays a great role in controlling Torque and frequency by tweaking the voltage.

Types Of Variable Frequency Inverter

Different VFI exist in the market. Some of the widely used VFI are as follows:

1.VSI type VFI

The term VSI refers to the Voltage source inverter. This type of VFI is especially known for smoothness in forming voltage waves. It usually consists of a rectifier, capacitor, and inverter. You can control the number of motors with these VFI devices.

2.CSI type

The word CSI is the abbreviation of the current source inverter. This device uses larger inductors, SCR-based rectifiers, and inverters. The working principle remains the same as that of the VFI. This device can save up energy that flows in revere direction.

3.PWM type

The word PWM refers to pulse width modulation. In this way, the duty cycle changes to change the power delivered. It uses fixed pulses of voltage to result in a sinusoidal waveform.

This device uses a diode bridge rectifier and a control unit. This device does not cause cogging and features a great power factor.

Why Make Use of Variable Frequency Inverter?

There are multiple reasons you should use a variable frequency inverter. Some most demanding reasons are as follows:

·Reduces Extra Energy Utilization

When you use a Variable Frequency Inverter, it results in 20 to 50% less energy consumption.

·Torque Control

You can control the motor speed or Torque with the Variable frequency inverter. An option exists to attach a rotary switch. This will play its part in adjusting the inverter frequency. You can utilize your conveyors and machines for different applications by tweaking speed settings.

·Alter the Direction of Rotation

Yes, you can change the direction of rotation by altering the inputs of the inverter. Doing this will enable you to operate your motor in either reverse or forward direction.

·Limitations On Torque

While using a frequency drive will make you set the limits on Torque as per your requirements. When a machine stops functioning, then VFI instantly stops the motor. In case of overloading, it will continue working unless overload contacts open.

·Eliminate Components Replacement

It eliminates the need for various components replacement, as you can alter the speed from minimum to maximum. You can do this without changing reduction components or gearboxes. It results in saving a lot of space as well as leads to a reduction in the costs that you spend on components.

·Convenient Start

VFI can provide low frequency on starting the motor or your system. You don’t need to use starters like start delta starters or complex wiring. They gradually enhance the speed of the motor until reaching its full potential.

Applications of Variable Frequency Inverter

Several applications exist for a variable frequency inverter. Some of the key applications are as follows:

- The VFI has a wide adaptation for usage induction motors to control the speed within a limit. Where it solely depends on the frequency.

- You can use it in controlling the conveyor belts. Conveyor belts are the key components in various industries, including beverages, food, medicine, and automation. You can also change the direction of rotation of the motor in these industries.

- The VFI devices have wide adaptation in the cooling system to control the temperature within a specific limit.

- Escalators and lifts also make use of smooth starting and stopping VFI features.

- Crushers in Mining operations and water pumps in various industries require VFI for convenient operation.

- Crane and Hoist also utilize a Variable frequency inverter to facilitate exact positioning and speed.

Verdict

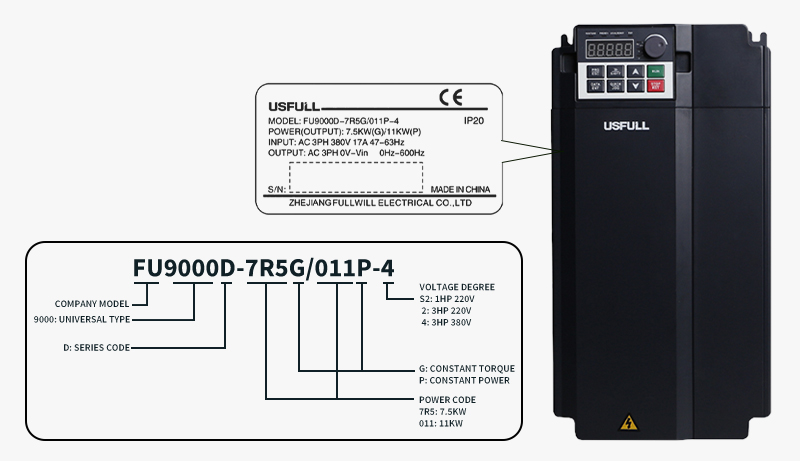

We have discussed everything about variable frequency inverters. The benefits and features of this device are worth it. You can directly employ the USFULL Variable frequency drive in your motors or fans systems.

This device is not only reliable but also affordable. It ensures greater protection for your components and helps you save costs in the long run. If you have any queries about this specific piece of device, then feel free to reach out. You can comment below for quality assistance.