Reason

When using a frequency converter (VFD) to control a high-power motor, particularly in applications requiring rapid stopping or frequent direction changes, the motor continues to rotate due to inertia during deceleration or stopping. This process converts the kinetic energy of the motor back into electrical energy, which flows back into the frequency converter’s circuitry and eventually into the power supply system. If this regenerated energy is not properly managed, it can damage the frequency converter, potentially leading to catastrophic failure of its power components.

To Prevent This Situation, The Following Measures Are Usually Taken

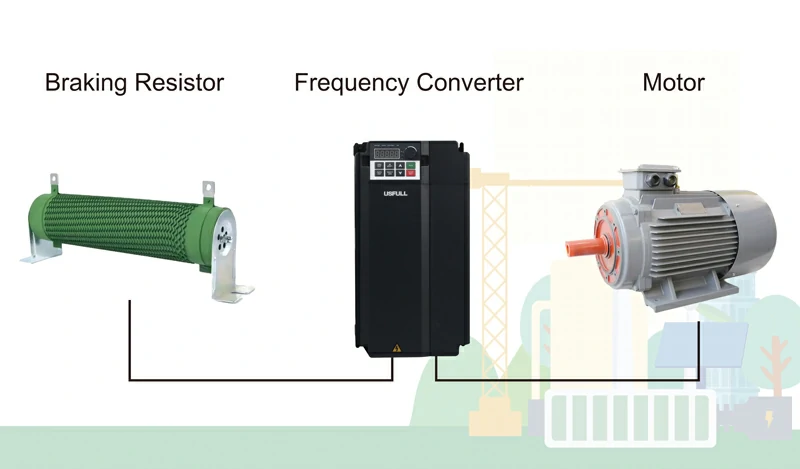

Install brake resistor:

A brake resistor provides an additional load during the motor’s regenerative state, dissipating the generated electrical energy as heat. This helps in quickly decelerating the motor. Brake resistors are typically used in conjunction with a braking unit (or braking chopper), which controls the connection and disconnection of the resistor.

Energy feedback unit (regenerative feedback unit):

In some applications, an energy feedback unit is used to conserve energy and reduce heat generation. This device converts the motor’s regenerated energy into a form suitable for the power grid and feeds it back into the grid, instead of wasting it as heat. This method is particularly useful in applications requiring frequent starting and stopping or rapid deceleration.

Use the built-in braking function of the frequency converter:

Some frequency converters are designed with built-in braking functions that manage regenerative energy without the need for external brake resistors. These VFD have a built-in braking function that safely dissipates excess energy and prevents overvoltage. To protect the frequency converter and other system components, it is essential to ensure safe and effective deceleration of the motor during rapid stops or frequent direction changes by using brake resistors or other braking devices.

A Frequency Converter with a Heavy Load That Is Not Equipped with a Braking Resistor Can Be Easily Damaged Due to the Following Reasons

Renewable energy issues:

Without a braking resistor or regenerative feedback, the excess energy generated during deceleration can cause overvoltage, leading to potential damage.

Overvoltage protection failure:

Frequency converters are typically equipped with overvoltage protection mechanisms that disconnect the power supply when voltage exceeds safe limits. However, if the protection settings are improper or the protection device malfunctions, excessive voltage can damage the internal components of the frequency converter.

The bearing capacity of internal capacitors and power components:

The DC bus capacitors and power components (such as IGBT) within the frequency converter have maximum voltage tolerances.Internal components like capacitors have limited capacity to handle surges. Exceeding their limits can result in catastrophic failure.

Heat damage:

Frequent switching of power components due to handling regenerative energy generates additional heat. If cooling is inadequate, this heat can lead to thermal damage, reducing the lifespan of the components or causing immediate failure.

Current surge:

Rapid acceleration or deceleration can cause current surges, putting immense stress on the electrical components and potentially leading to failure.

Conclusion

To avoid these issues, incorporating a brake resistor and braking unit into the frequency converter system is essential. A brake resistor dissipates the motor’s regenerative energy as heat, protecting the frequency converter from excessive voltage damage. If the system design does not allow for the use of a brake resistor, an energy feedback unit (regenerative feedback unit) can be considered. This device returns regenerative energy to the power grid, improving system efficiency and protecting the frequency converter. Proper management of regenerative energy is crucial in ensuring the safety and longevity of frequency converters in high-power motor applications.