Are you facing energy inefficiency and high operational costs in your HVAC systems? These problems not only drain your budget but also affect overall system performance. Variable Frequency Drives (VFDs) are the perfect solution to optimize energy use, reduce costs, and enhance your HVAC system’s performance. Let’s explore how VFDs can benefit you.

Variable Frequency Drives (VFDs) control the speed of motors in HVAC systems, providing significant energy savings and efficiency improvements. By adjusting motor speed based on demand, VFDs optimize performance and reduce energy consumption, making them a crucial component in modern HVAC systems.

Understanding how VFDs work can significantly transform your HVAC operation. Keep reading to discover how you can boost efficiency and save costs.

How Variable Frequency Drives Work in HVAC Systems?

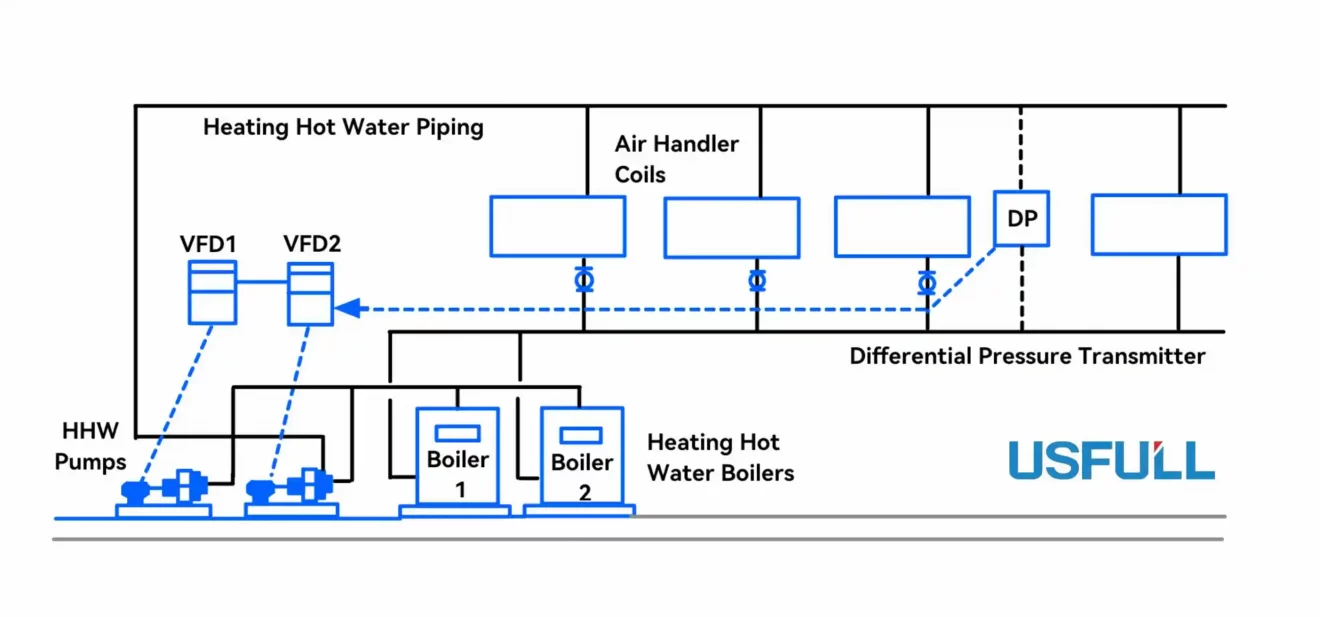

Variable Frequency Drives (VFDs) in HVAC systems regulate the speed of electric motors by adjusting the frequency of the electrical supply. These drives convert the incoming AC (alternating current) voltage to DC (direct current) and then back to AC, but at a variable frequency. By doing so, VFDs ensure that motors run at optimal speeds according to the demand rather than operating at full speed all the time. In HVAC systems, this is especially beneficial for air handling units, pumps, and fans, as it ensures they only use the power they need.

The result is smoother and more efficient system operation, which reduces wear and tear on components and prolongs the life of the system. Additionally, it ensures energy is used only when required, avoiding the inefficiencies of running motors at constant, unnecessary speeds.

How do VFDs Enhance the Efficiency of HVAC Systems?

VFDs enhance HVAC system efficiency by providing precise control over motor speed and reducing energy consumption. Traditional HVAC systems operate with motors running at a constant speed, regardless of actual demand. VFDs, however, adjust motor speed to match real-time requirements, which results in a reduction of energy waste.

For example, when cooling or heating demand is low, the VFD reduces the speed of the compressor or fan, ensuring the system uses less power. As demand increases, the VFD ramps up the motor speed to meet the required load. This dynamic approach to energy consumption leads to substantial energy savings and a more efficient HVAC operation.

In addition to reducing energy use, VFDs also improve system stability by reducing mechanical stress on motors. This not only enhances efficiency but also extends the lifespan of the HVAC equipment.

Benefits of Using VFDs in HVAC Systems

The benefits of using Variable Frequency Drives (VFDs) in HVAC systems are numerous and impactful. Some of the key advantages include:

- Energy Savings:VFDs reduce energy consumption by adjusting motor speeds based on actual demand, leading to substantial energy savings over time.

- Cost Reduction:With lower energy consumption, operational costs decrease, allowing companies to enjoy reduced electricity bills and increased profitability.

- Improved Comfort:VFDs provide smoother and quieter operation of HVAC systems, improving the comfort levels in the environment, whether in an office, commercial building, or industrial facility.

- System Longevity:By controlling motor speed and reducing wear and tear, VFDs extend the lifespan of HVAC components, reducing the frequency of repairs and replacements.

- Environmental Impact:As energy consumption decreases, so does the carbon footprint of the building or facilit VFDs contribute to more sustainable operations, making them an eco-friendly choice.

In short, VFDs enhance HVAC system efficiency by providing dynamic control over motor speeds, optimizing energy use, and offering long-term savings.

What Is the Purpose of a Variable Frequency Drive (VFD)?

The primary purpose of a Variable Frequency Drive (VFD) is to control the speed of an electric motor, thereby improving the performance and efficiency of the system it is integrated into. In HVAC systems, this control allows the system to adjust motor speed based on varying environmental demands, such as the temperature or airflow requirements, rather than maintaining a constant speed.

By varying the frequency of the electrical power sent to the motor, the VFD ensures that the motor operates at the exact speed required for the current load, which improves energy efficiency. This capability of VFDs leads to better regulation of airflow, temperature, and pressure, providing better overall system control.

In essence, the purpose of a VFD in HVAC is to optimize system performance, improve energy savings, and reduce operational costs by offering precision control over motor speeds.

How to Choose a Variable Frequency Drive?

Selecting the right Variable Frequency Drive (VFD) for your HVAC system depends on several factors, including:

- Motor Specifications:Ensure that the VFD is compatible with the motor’s voltage, current, and power ratings. The VFD should match the motor’s operating range for optimal performance.

- System Requirements:Consider the specific needs of your HVAC system, such as the required speed range and control precision. Some systems may require more advanced features, like a multi-motor control or integrated communication.

- Efficiency Standards:Opt for VFDs that meet energy efficiency standards to ensure you achieve the maximum energy savings from your HVAC system.

- Ease of Integration:Choose VFDs that are easy to install and integrate with your existing system infrastructure. Ensure that the VFD is compatible with other components such as sensors, controllers, and communication systems.

- Brand Reputation and Warranty:Consider VFDs from reputable brands that offer good warranties and customer support, ensuring long-term reliability.For example, the brand USFULL is good

By carefully evaluating these factors, you can choose the best VFD for your HVAC system, maximizing both efficiency and cost savings.

Conclusion

In summary, Variable Frequency Drives (VFDs) are essential for improving the efficiency and performance of HVAC systems. By controlling motor speed, VFDs save energy, reduce operational costs, and extend system life. When selecting a VFD, make sure to consider motor specifications, system requirements, and efficiency standards to ensure you get the most out of your HVAC system.

This concludes the article on Variable Frequency Drives in HVAC. I hope this helps in understanding how VFDs can enhance your HVAC operations!