The Hidden Danger: A Blown IGBT Can Bring Your System to a Halt

A failed IGBT module in your solar pump inverter can cause sudden shutdowns, costly repairs, and even fire hazards. If not prevented, it could lead to severe equipment failure. Understanding the reasons behind IGBT failures is key to maintaining stable operation and avoiding unnecessary losses.

IGBT failures in solar pump inverters occur due to electrical surges, overheating, design flaws, and improper maintenance. Preventative measures can significantly reduce the risk of unexpected breakdowns.

Why does this happen, and how can you prevent it? Read on to find out.

How IGBT Modules Work?

IGBT (Insulated Gate Bipolar Transistor) modules are critical components in solar water pump inverters and variable frequency drives. These modules function as high-speed electronic switches, regulating power flow by alternating between conducting and blocking states. By controlling voltage and current, they help convert DC power from solar panels into AC power for running motors. The combination of MOSFETs’ fast switching ability and BJTs’ high power capacity makes them ideal for variable frequency inverters. However, if they experience voltage spikes, excessive current, or thermal stress, they can fail, causing serious damage to the solar pump inverter system.

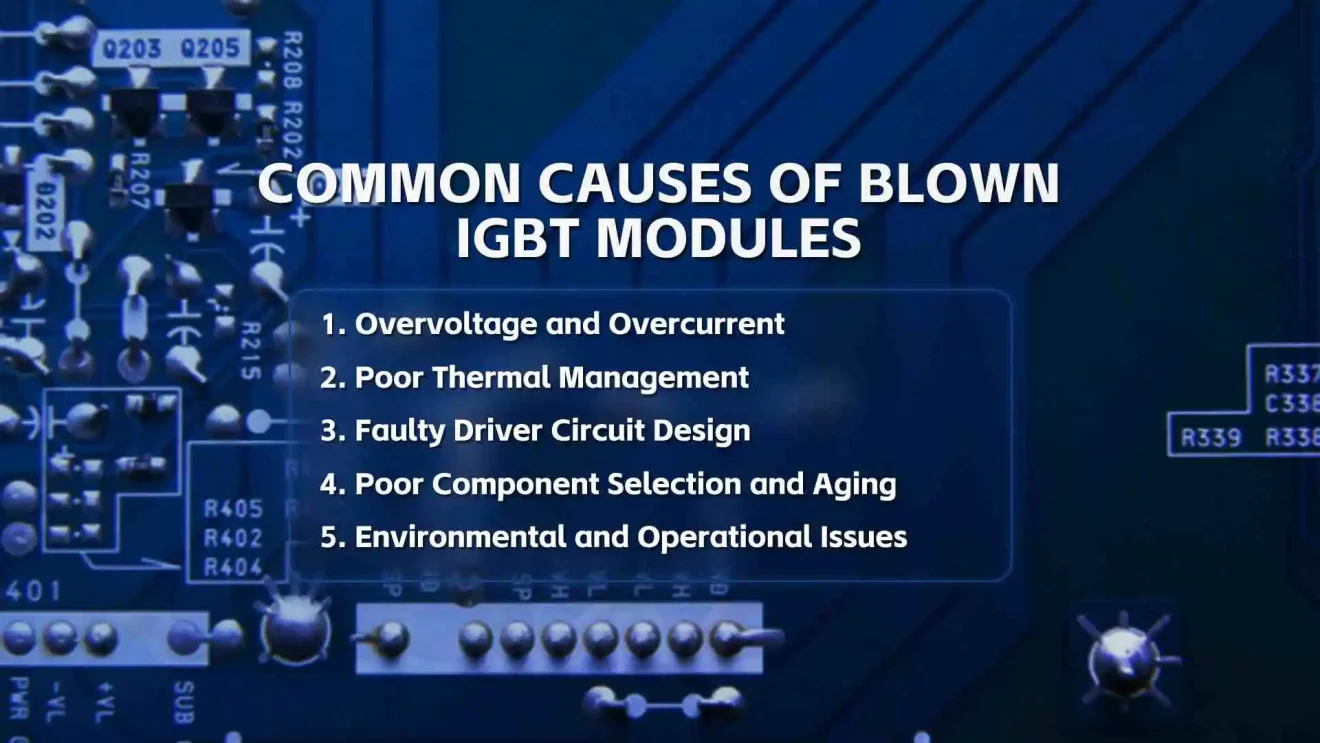

Common Causes of Blown IGBT Modules

1. Overvoltage and Overcurrent

Sudden voltage spikes from grid fluctuations, lightning strikes, or switching transients can exceed the IGBT’s voltage rating, leading to insulation breakdown. Similarly, rapid current surges caused by motor startup, output short circuits, or drive malfunctions can push the IGBT beyond its limit, causing it to overheat and fail.

2. Poor Thermal Management

IGBT modules generate significant heat during operation. If heat sinks, cooling fans, or liquid cooling systems fail to dissipate heat effectively, the module temperature can exceed safe limits. High temperatures degrade insulation materials, increase electrical resistance, and ultimately cause IGBT burnout.

3. Faulty Driver Circuit Design

The IGBT driver circuit controls the switching process. If the driver voltage is too low, it can cause partial conduction, increasing heat dissipation. Poorly designed gate resistors, dead-time settings, and PWM signals can result in inefficient switching, leading to premature failure.

4. Poor Component Selection and Aging

IGBTs with insufficient voltage or current ratings for the application may fail prematurely. Additionally, capacitor aging, solder joint fatigue, and loose connections in the solar pump inverter can lead to sudden failures due to increased resistance and thermal stress.

5. Environmental and Operational Issues

Unstable grid conditions, harmonic distortion, three-phase imbalances, or even improper handling during maintenance can contribute to IGBT failures. Incorrect wiring, dust accumulation, or moisture ingress may also accelerate module degradation.

What to Do in Case of Emergency After an IGBT Blows Up?

Shut Down the Inverter Immediately – Disconnect the power supply to prevent further damage.

Inspect for Visible Damage – Look for burnt components, melted solder, or smoke residue.

Measure Circuit Integrity – Use a multimeter to check the IGBT module’s resistance (short circuits indicate failure).

Examine the Driver Circuit – Verify gate drive voltage, dead-time settings, and protection circuits.

Replace the Faulty Module – Use a compatible, high-quality IGBT module and ensure proper heat dissipation measures.

Key Measures to Prevent IGBT Blow-ups

1. Improve Circuit Protection

Install RC snubber circuits, TVS diodes, and fast-acting fuses to absorb transient voltage spikes. Use Hall sensors and overcurrent protection to limit current surges.

2. Enhance Cooling Efficiency

Optimize heat sink design, airflow paths, and thermal grease application to improve heat dissipation. Regularly clean cooling fans and check for obstructions.

3. Ensure Proper Component Selection

Select IGBT modules with at least twice the working voltage rating and allow sufficient current headroom. Avoid using outdated or low-quality components.

4. Regular Maintenance and Monitoring

Conduct thermal imaging inspections, check gate signals using an oscilloscope, and monitor voltage/current waveforms. Implement real-time monitoring for temperature and power fluctuations.

5. Train Maintenance Personnel

Provide in-depth training on variable frequency inverters, IGBT operation, and failure diagnostics. Proper handling and troubleshooting can prevent unintentional failures.