Introduction

With the advancement of industrial automation, variable frequency drive (VFD) screw air compressors have been widely used in the manufacturing industry due to their energy efficiency, high performance, and stability. However, traditional air compressor variable frequency inverter systems still face challenges such as complex wiring of control circuits, time-consuming installation and maintenance, and difficulty in troubleshooting faults, which affect equipment reliability and operational efficiency.

To address market demands, USFULL has independently developed a high-performance frequency inverter, optimizing system integration, improving reliability, and making installation and maintenance more convenient. This article presents a case study of the USFULL frequency inverter applied in a permanent magnet synchronous air compressor, detailing its advantages and actual operational results.

Advantages of USFULL VFD in Permanent Magnet Synchronous Air Compressors

Compared to traditional asynchronous motor variable speed drive (VSD) systems, the USFULL inverter VFD for air compressors offers the following benefits:

- Direct Shaft Connection for Higher Transmission Efficiency

The permanent magnet synchronous motor (PMSM)and compressor host adopt an embedded direct shaft connection structure, reducing mechanical losses compared to traditional belt or coupling transmissions, achieving 100% transmission efficiency. - Maintenance-Free Motor, Lower Operational Costs

By adopting a bearing-free design, the risk of motor bearing failuresis completely eliminated, reducing maintenance costs and improving system reliability. - Compact Size, Easy Installation and Removal

The variable frequency invertermotor is only one-third the size of a conventional frequency-adjusted motor, reducing equipment footprint and simplifying installation and removal. - High Efficiency at Low Speeds, Superior Energy Savings

Even at low speeds, the PMSM maintains high efficiency, achieving 10%-30% greater energy savingscompared to traditional variable frequency asynchronous motors. - Fast Response Time for Enhanced System Stability

The synchronous motorhas a fast response speed, significantly improving pressure regulation performance, reducing exhaust response time, and enhancing the overall operational efficiency of the air compressor system.

Practical Application of USFULL Frequency Inverter in Air Compressors

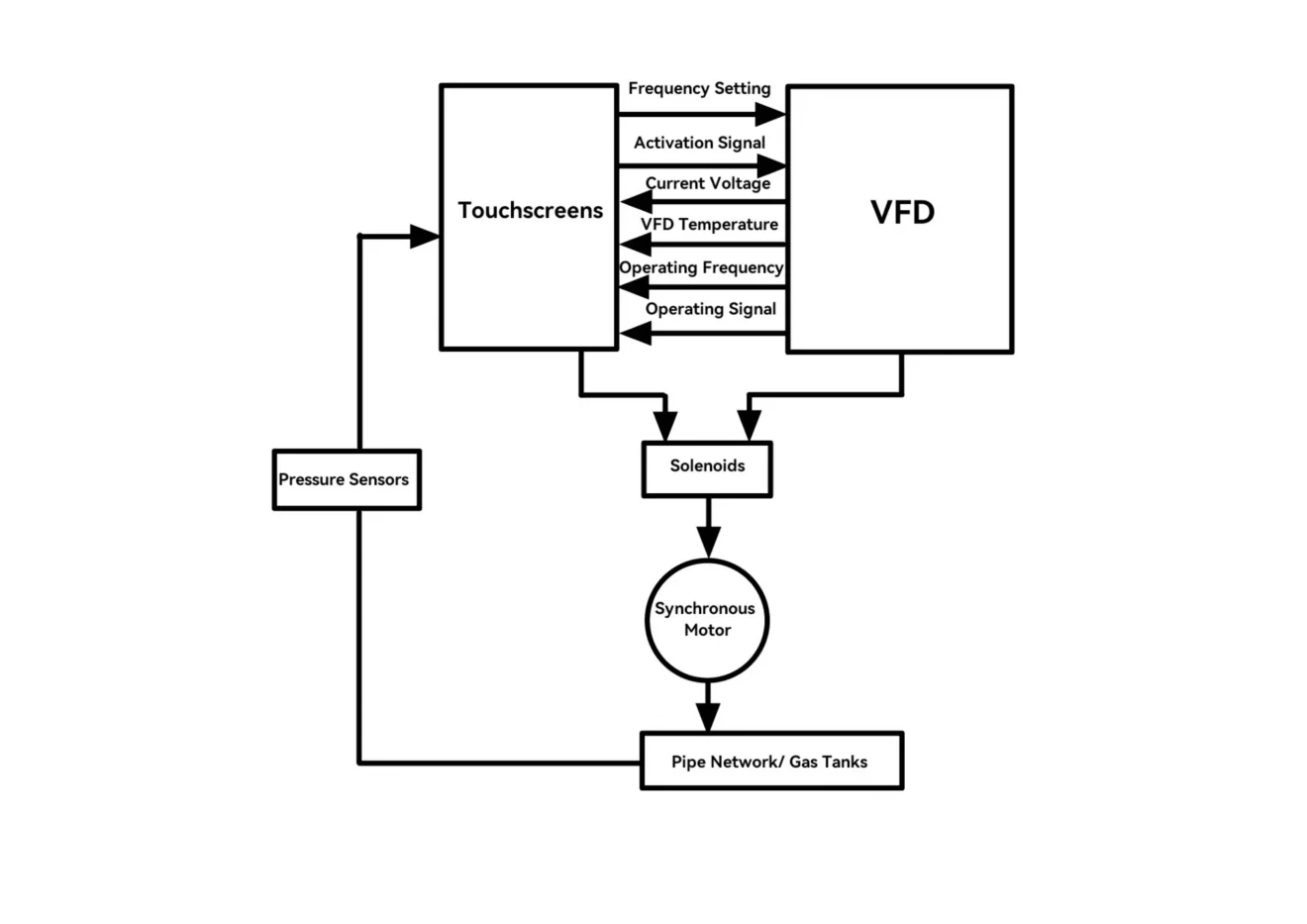

1. Air Compressor System Diagram

The application architecture of the USFULL frequency inverter with the air compressor control system is as follows:

Core Equipment:

- USFULL variable frequency drive (VFD)

- Permanent Magnet Synchronous Motor (PMSM)

- 6080M Air Compressor Controller

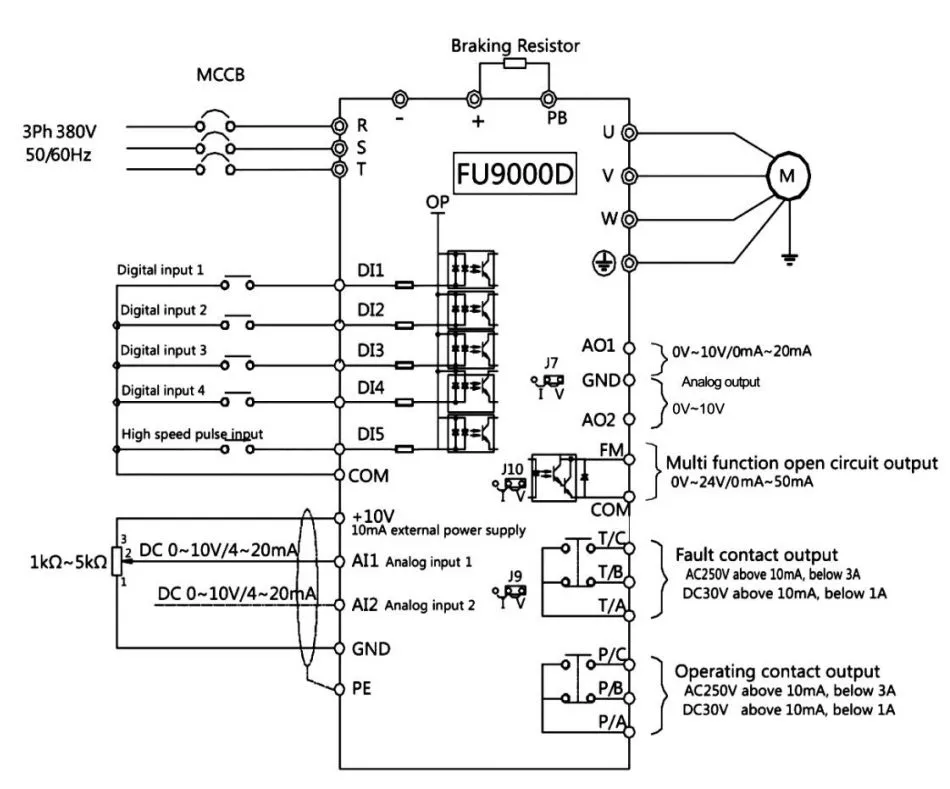

2. Electrical Wiring of the USFULL Frequency Inverter

Main Circuit Wiring:

- The VFDis connected to the motor and controller to form a complete control system

- Terminal S1controls the start/stop of the air compressor

Fault signals from the frequency inverter are sent to the controller to trigger emergency shutdown if necessary

3. Phase Sequence Confirmation & Trial Operation

Phase Sequence Check:

- Fan Direction Check: If the fan rotates in the wrong direction, adjust the fan wiring to ensure correct rotation

- Main Motor Phase Confirmation: Perform a test run of the main motor and adjust the variable frequency drive (VFD) output wiringif necessary

Trial Operation:

- Start the 6080M controllerand check if the air compressor operates smoothly under load

Monitor output current, voltage, and temperature of the frequency inverter to ensure stable operation

Application Results & Conclusion

The successful application of the USFULL VFD in permanent magnet synchronous air compressors highlights its outstanding capabilities in high-efficiency drive technology and intelligent control:

- Easy Installation: Simplified wiring reduces installation time and improves system integration

- Energy Saving: High efficiency at low speeds, delivering superior energy savings over traditional asynchronous motors

- Stable Operation: Advanced control technology ensures long-term reliability of air compressors

- Low Maintenance: The bearing-free motor designminimizes downtime and maintenance costs

As industries demand greater efficiency, energy savings, and smart automation, USFULL’s inverter VFD will continue to play a crucial role in the air compressor sector, providing superior variable speed drive (VSD) solutions for customers worldwide!

USFULL specializes in variable frequency drives (VFD), solar pumping inverters, and other industrial automation solutions. Contact us today to learn more!