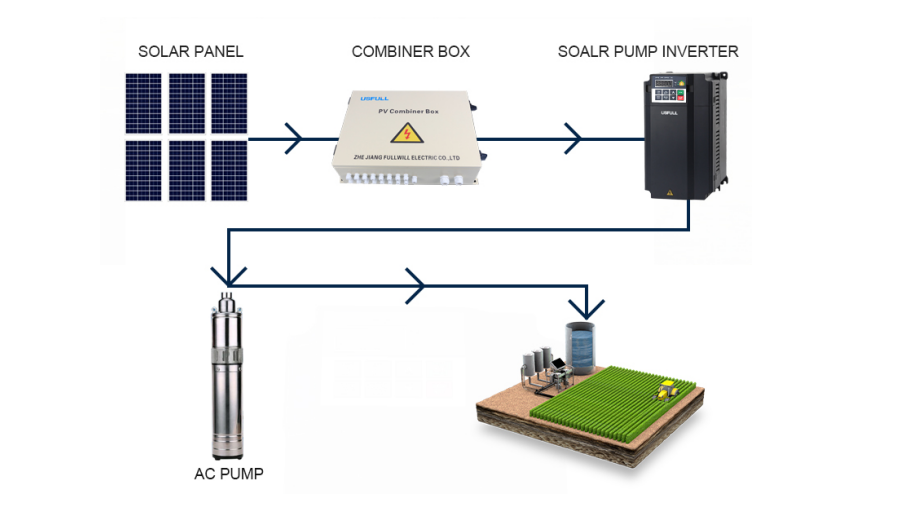

Unleash the potential of your machinery with our cutting-edge Variable Frequency Drives (VFD). Engineered for precision control, VFDs deliver optimized performance across industries. From manufacturing to HVAC, experience unrivaled energy efficiency and enhanced process automation. Tailor your operations today with a VFD that’s fine-tuned to your unique needs. Boost productivity, lower costs, and step into a harmonious synergy of technology and efficiency – contact us now!

After years of highly efforts in technical R&D, with the support and trust from users, USFULL has achieved remarkable achievements. Products are sold to more than 90 countries and regions domestic and abroad. USFULL brand will be recognized by everyone!