When sourcing solar pump inverters, buyers often face the challenge of differentiating between good and subpar quality. The consequences of poor quality are far-reaching—reduced system efficiency, frequent breakdowns, and increased maintenance costs. So, how can you ensure your solar pump inverter is of top-notch quality? Let’s explore key strategies to ensure your investment lasts long and operates optimally.

When purchasing solar pump inverters, it’s vital to look beyond just meeting standards; exceeding them ensures long-term performance and reliability. This article explores how testing, features, and quality control contribute to a top-performing solar water pump inverter.

Ensuring quality in solar pump inverters isn’t just about meeting minimum standards; it’s about surpassing them. From semi-finished product testing to load testing and looking for key features, these steps ensure longevity and efficiency. Keep reading to discover how to make the best choice.

What Does Quality Mean for Solar Pump Inverters?

When discussing quality in solar pump inverters, it’s crucial to think beyond the surface-level attributes like price and appearance. Quality means reliability, efficiency, and durability in real-world conditions. A high-quality solar pump inverter must perform consistently over long periods, with minimal maintenance, while also being resistant to environmental challenges like dust, heat, and moisture. Furthermore, its efficiency in converting DC energy from solar panels to AC energy for the water pump is essential. A reliable solar pump inverter should meet or exceed industry standards, including certifications like IEC 61800 and IEC 62109, and provide a stable output to ensure the long-term success of the solar pumping system.

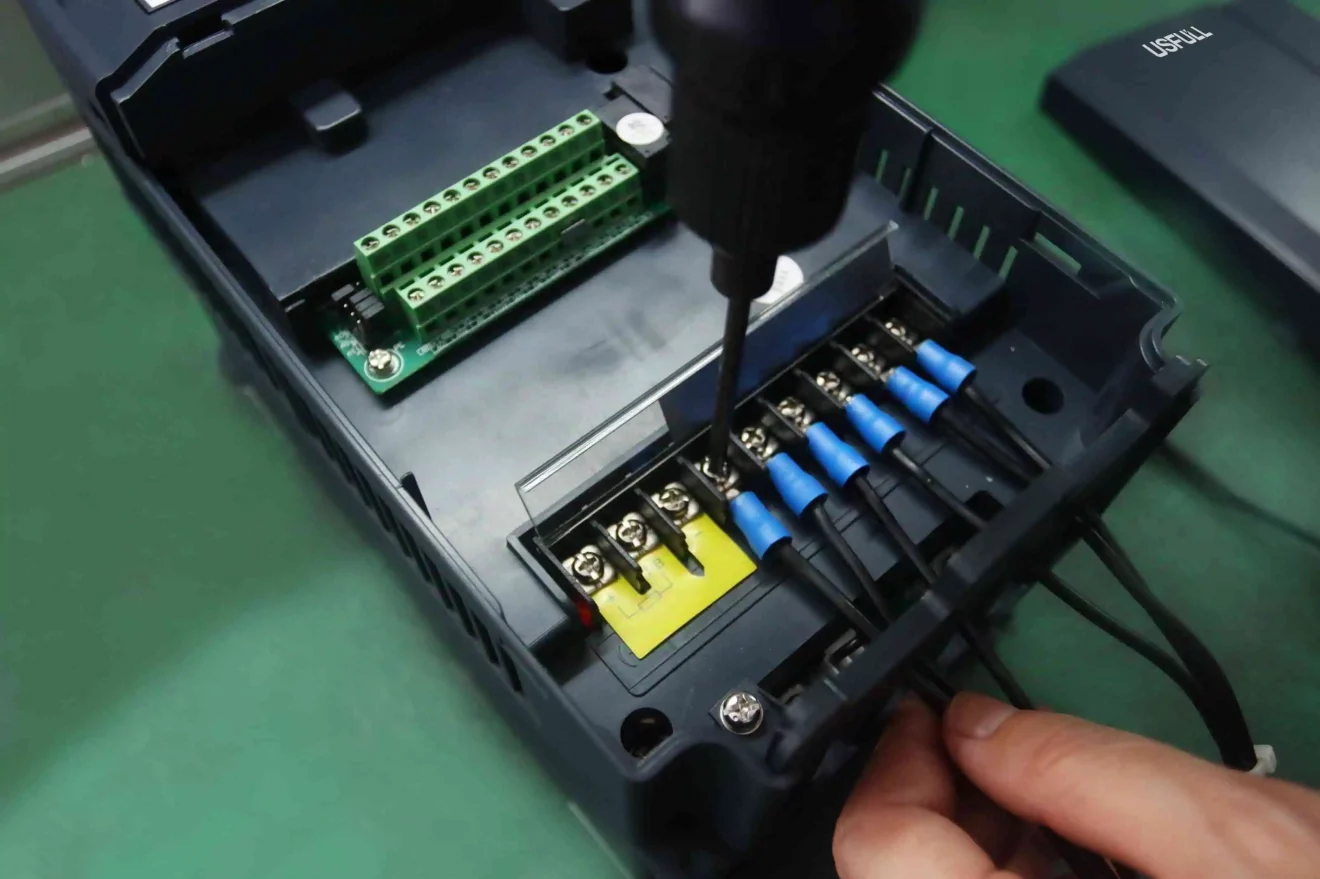

Semi-finished Product Testing: Why Is It Crucial?

The importance of semi-finished product testing cannot be overstated. During the production process of solar pump inverters, before the final assembly, semi-finished product testing ensures that critical components such as the circuit board, connectors, and capacitors meet the required specifications. These tests act as a safeguard, catching potential issues before they affect the final product. If a component fails, it can impact the overall performance of the inverter, potentially leading to downtime or a complete system failure. Thorough semi-finished product testing provides early detection of defects, ensuring that only the highest quality parts make it to the final assembly.

Load Testing: How Do We Mimic Real-world Conditions?

Once the semi-finished products are assembled, load testing plays a pivotal role in evaluating how well the inverter performs under real-world conditions. Load testing simulates the operational environment, including the varying loads a solar pump inverter may face during operation. By testing under different conditions, such as high temperatures, fluctuating voltage levels, and various water pump demands, manufacturers can ensure that the inverter performs optimally under stress. This step is essential because it reveals any weaknesses in the inverter’s design that might only become apparent under operational load. Effective load testing assures that the inverter will continue to perform efficiently even under harsh conditions, minimizing the risk of failures.

The Bottom Line: Why Do These Tests Matter?

In the world of solar pump inverters, comprehensive testing isn’t just a formality; it’s essential for guaranteeing performance and longevity. Every test, from semi-finished product checks to rigorous load testing, is designed to prevent failures that could lead to costly repairs or replacements. These tests mimic real-world scenarios, allowing manufacturers to fine-tune the design and components of their inverters before they reach the customer. By investing in thorough testing, manufacturers ensure that their products can withstand the long-term demands of solar water pumping systems. For buyers, this means peace of mind knowing that their solar pump inverter will not only meet standards but exceed expectations in terms of efficiency and reliability.

Key Features to Look for in Solar Water Pump Inverters

When purchasing a solar water pump inverter, it’s essential to focus on specific features that ensure the product’s quality and efficiency. These features include:

Efficiency: A high-quality solar pump inverter should boast a high conversion efficiency, minimizing energy losses during the conversion process. This directly impacts the overall system’s efficiency and reduces electricity costs.

Protection Mechanisms: Look for inverters that offer comprehensive protection against overvoltage, overcurrent, and short circuits. These safeguards prevent damage to the inverter and the connected components, enhancing the system’s lifespan.

Durability: Solar pump inverters should be built to withstand environmental factors like heat, moisture, and dust. A well-designed enclosure ensures that the inverter operates effectively in harsh weather conditions.

User-friendly Interface: A top-tier solar pump inverter will have an intuitive interface, enabling easy setup, configuration, and monitoring. This can include features like remote monitoring via apps, real-time data display, and easy-to-understand diagnostics.

Variable Frequency Drive (VFD): Inverters with a built-in VFD are essential for controlling the pump’s speed based on solar energy availability, allowing for optimal energy use.

Compliance with Standards: Ensure that the inverter meets local and international certifications, such as UL, CE, and ISO standards, which are indicative of rigorous quality control and testing.

These features work together to guarantee that your solar pump inverter will deliver top-notch performance for years to come, minimizing maintenance costs and ensuring optimal operation.

Conclusion

To summarize, ensuring the quality of your solar pump inverter requires a thorough understanding of testing processes, key features, and performance standards. From semi-finished product checks to load testing and the search for essential features, a top-notch inverter is one that exceeds industry standards. Quality matters—don’t settle for less.