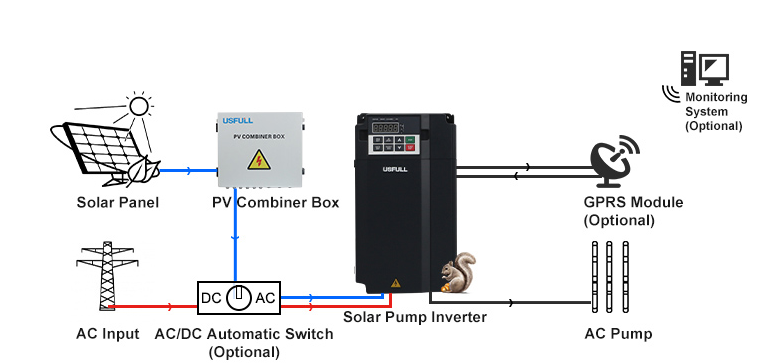

Connecting a solar pump inverter, also known as a solar VFD or solar water pump inverter, to a combiner box is a crucial step in setting up solar power systems and other applications requiring precise control over electrical motors. The process involves several key considerations, from understanding the functions of each component to ensuring proper installation and connection. This article will guide you through the entire process, covering important topics such as the functions of the Solar Pump Inverter and combiner box, pre-installation checks, installation methods, and debugging.

Functions of Solar Pump Inverter and Combiner Box

Solar Pump Inverter

A solar pump inverter is the bridge between a solar power station and the electrical system, performing several key functions:

- Energy Conversion: Efficiently converts DC power generated by solar panels into AC power.

- Maximum Power Point Tracking (MPPT): Automatically adjusts operating conditions to ensure solar panels operate at their maximum power point, maximizing energy output.

- Smart Monitoring: Monitors system performance in real-time, including voltage, current, and power, enabling remote monitoring and fault diagnosis.

- Protection Features: Includes multiple protection functions such as short circuit, overload, and islanding protection to ensure safe and stable operation.

Combiner Box

A combiner box in solar PV systems aggregates multiple DC inputs from solar panels into a single DC output. This output is then fed into an inverter, which converts it into AC power for use in the grid or electrical systems. Key functions of a combiner box include:

- Circuit Protection:Includes fuses or circuit breakers to protect against overcurrent and short circuits.

- Simplified Wiring:Reduces the complexity of wiring by consolidating multiple inputs into a single output.

- Monitoring and Maintenance:Often equipped with monitoring devices to check system performance and simplify maintenance tasks.

How to Check the Inverter and Combiner Box Before Installation?

Solar Pump Inverter and Combiner Box Inspection

Equipment Inspection:

- Check the inverter, combiner box, and accessories (cables, connectors, mounting brackets) for damage.

- Verify that keys, certificates, warranty cards, and user manuals are complete and specifications meet design requirements.

Environmental Inspection:

- Assess installation site conditions, including temperature, humidity, and wind speed, to ensure they meet equipment requirements.

Drawing Verification:

- Cross-reference installation locations and wiring paths with construction drawings to ensure accuracy.

What Are the Installation Methods of Inverter and Combiner Box?

The installation methods for solar water pump inverter and combiner boxes can vary based on site conditions and equipment characteristics. Common methods include:

solar pump inverter Installation

Wall-Mounted Installation:

- Suitable for flat, sturdy indoor or outdoor walls.

- Ensure wall stability and use expansion or chemical anchors for secure bracket installation.

Pole-Mounted Installation:

- Applicable where suitable poles or supports are available.

- Verify that poles meet diameter, height, and load requirements, and use specialized clamps to secure the inverter.

Ground Installation:

- Suitable for flat surfaces with ample space.

- Install a foundation or base to ensure stability.

Combiner Box Installation

Wall-Mounted Installation:

- Ideal for compact layouts and convenient access to multiple panel strings.

- Mount securely using appropriate hardware to support the box.

Pole-Mounted Installation:

- Ensure poles meet strength requirements and use clamps and brackets for mounting

Ground Installation:

- Place on a stable base or platform to ensure easy access and protection from environmental factors.

Installation Precautions

Taking the following precautions during installation helps ensure equipment safety and performance:

- Moisture Protection:Avoid installing inverters and combiner boxes in damp or water-prone areas.

- Sun and Heat Protection:Shield equipment from direct sunlight and high temperatures to prevent overheating.

- Load Bearing Check:Verify that walls, poles, or floors can support the equipment’s weight.

Weather Considerations: Avoid installation during rain or snow to prevent water damage and ensure installation quality.

Outlet Wiring Method

Proper outlet wiring is essential to ensure the system’s electrical integrity and safety:

Cable Stripping:

- Use cable strippers or blades to remove the outer insulation, being careful not to damage the inner insulation or conductors.

Waterproof Gland Installation:

- Install waterproof glands immediately after stripping the cable. Select glands that match cable specifications and ensure secure, sealed installation.

Cable Securing:

- Secure cables before connecting to the inverter or combiner box to prevent movement or sagging.

- Choose secure points along the cable path and use cable clips or ties to fix cables in place, avoiding excessive tension.

How to Connect the solar pump inverter to the Combiner Box?

To connect the solar pump inverter to the combiner box, follow these steps:

Prepare Cables:

- Select cables with appropriate ratings for voltage and current.

- Strip insulation from cable ends and attach suitable connectors.

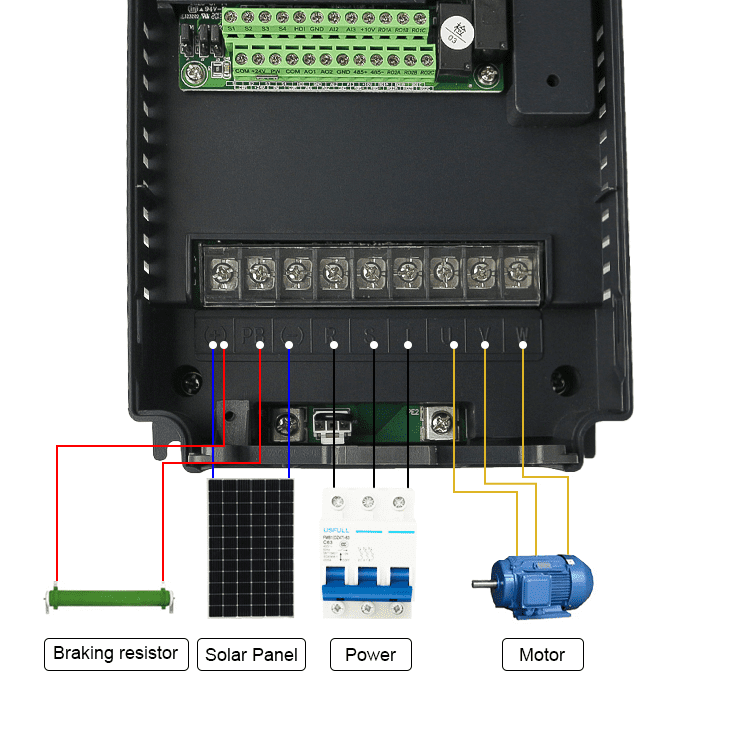

Connecting DC products:

- “+”pole of each strings solar panel is connected to “+” pole of fuses in combiner box.

- “-“pole of each strings solar panel is connected to “-” pole of fuses in combiner box.

- Connect the cable from solar panel to DC breaker.USFULL DC MCB is non-polarity.You can use left pole as + andiright pole as -.The solar panel input on bottom side of breaker.

- “+”pole and “-” pole of the DC breaker are connected to the inverter.

Secure Connections:

- Tighten all connections to prevent loosening due to vibration or thermal expansion.

- Use cable ties or clamps to organize and secure cables.

Verify Connections:

- Double-check all connections for accuracy and security.

- Ensure that no stray wires or loose connections are present.

How to Debug and Accept?

After installation, debugging and acceptance testing are essential to ensure the system operates correctly:

Initial Power-On:

- Power on the system and observe the inverter’s startup sequence.

- Check for error codes or warnings on the inverter’s display panel.

Functional Testing:

- Test the motor’s operation by varying the speed and observing performance.

- Ensure the inverter responds correctly to control signals.

Monitoring and Logging:

- Use monitoring tools to log system performance and identify potential issues.

- Check for voltage, current, and frequency deviations.

Acceptance Criteria:

- Verify that the system meets all performance and safety criteria.

- Conduct a final inspection and obtain approval from relevant stakeholders.

In conclusion, the connection between a solar pump drive and a combiner box is a critical aspect of solar PV system installation. By following these guidelines and understanding the functions and installation methods of each component, you can ensure a reliable and efficient setup. Regular maintenance and monitoring are vital for long-term performance and safety.