Titre : Convertisseur de puissance ou convertisseur de fréquence : comprendre les principales différences

Meta Description : Découvrez les distinctions entre les convertisseurs de puissance et les convertisseurs de fréquence. Apprenez comment ces dispositifs, utilisés pour la conversion de l'énergie électrique, varient en termes de fonctionnalités, d'applications et d'avantages. Prenez des décisions éclairées pour vos besoins en matière de conversion d'énergie.

Introduction :

Dans ce guide complet, nous nous penchons sur les caractéristiques opposées des convertisseurs de puissance et des convertisseurs de fréquence. En explorant leurs fonctionnalités, leurs applications et leurs avantages, vous obtiendrez des informations précieuses pour sélectionner le dispositif le mieux adapté à vos besoins spécifiques en matière de conversion de l'énergie électrique.

Le corps :

1. Convertisseurs de fréquence :

Les convertisseurs de fréquence, également connus sous le nom d'entraînements à fréquence variable (EFV), permettent un contrôle précis de la vitesse et du couple du moteur. En ajustant dynamiquement la fréquence et la tension fournies au moteur, ces dispositifs optimisent la vitesse de rotation, ce qui se traduit par une amélioration des performances et de l'efficacité énergétique. Largement utilisés dans les secteurs industriels, les variateurs de fréquence trouvent des applications dans les pompes, les ventilateurs, les convoyeurs, les machines-outils et diverses autres machines qui nécessitent une régulation contrôlée de la vitesse.

La sélection de la fréquence de commutation d'un onduleur implique la prise en compte de divers facteurs tels que l'efficacité, le coût, la taille et les interférences électromagnétiques (EMI). La fréquence de commutation détermine la vitesse à laquelle les interrupteurs de puissance du circuit de l'onduleur s'allument et s'éteignent. Des fréquences de commutation plus élevées permettent généralement d'obtenir des variateurs plus petits et plus efficaces, mais peuvent augmenter les interférences électromagnétiques.1.1. Types de variateurs de vitesse:1.1.1 Variateur à basse fréquence :

Un onduleur basse fréquence fait généralement référence à un onduleur qui fonctionne à des fréquences inférieures à 60 Hz, qui est la fréquence standard du courant alternatif dans de nombreuses régions. Les onduleurs basse fréquence sont souvent utilisés pour des applications spécifiques telles que l'alimentation de certains types d'équipements ou d'appareils.

1.1.2 Onduleur haute fréquence :

Un onduleur haute fréquence fonctionne à des fréquences supérieures aux fréquences standard de 50 ou 60 Hz. Ces onduleurs sont couramment utilisés dans des applications telles que les alimentations à découpage, les onduleurs solaires et certaines commandes de moteur. Les fréquences plus élevées permettent d'utiliser des circuits de conversion d'énergie plus petits et plus efficaces.

Il est important de noter que les détails et les capacités spécifiques des convertisseurs de fréquence peuvent varier en fonction du fabricant et de l'application envisagée. Il est recommandé de consulter la documentation du fabricant ou de demander l'avis d'un expert pour obtenir des informations spécifiques sur un modèle particulier de convertisseur.

1.2 Lignes directrices pour le choix de la fréquence de commutation :

- Efficacité : Des fréquences de commutation plus élevées peuvent améliorer le rendement de l'onduleur et réduire les pertes de puissance. Toutefois, à très haute fréquence, les pertes de commutation et d'autres facteurs peuvent annuler les gains d'efficacité.

- Coût : des fréquences de commutation plus élevées nécessitent souvent des composants plus avancés et plus coûteux. Par conséquent, le coût de l'onduleur peut augmenter avec des fréquences plus élevées. Il est important de trouver un équilibre entre le coût et les performances.

- Taille et poids : des fréquences de commutation plus élevées permettent d'utiliser des composants plus petits et plus légers tels que des condensateurs et des inductances. Cela peut conduire à une conception plus compacte et plus légère de l'onduleur.

- Interférences électromagnétiques (EMI) : la commutation à des fréquences élevées peut générer davantage d'EMI, ce qui peut affecter d'autres appareils électroniques ou provoquer des interférences dans les systèmes de communication. Si les interférences électromagnétiques sont un problème, il peut être nécessaire de limiter la fréquence de commutation ou d'incorporer des techniques supplémentaires de filtrage des interférences électromagnétiques.

- Pour calculer la fréquence de commutation d'un onduleur, il faut tenir compte des caractéristiques de la charge et des performances souhaitées de l'onduleur. Parmi les facteurs à prendre en compte figurent la forme d'onde de la tension de sortie souhaitée, la nature de la charge (résistive, inductive, capacitive) et le schéma de contrôle utilisé.

2. Onduleurs de puissance :

Les onduleurs sont des appareils polyvalents qui convertissent le courant continu (CC) provenant de sources telles que les batteries, les panneaux solaires ou les alternateurs des véhicules en courant alternatif (CA). Ils permettent le fonctionnement d'appareils et de dispositifs alimentés en courant alternatif dans des scénarios où seule l'alimentation en courant continu est disponible. Les onduleurs sont essentiels pour les solutions d'alimentation de secours, les systèmes d'énergie renouvelable hors réseau et les solutions d'alimentation mobile pour les véhicules de loisirs, les bateaux ou les camions.

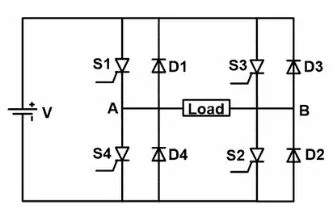

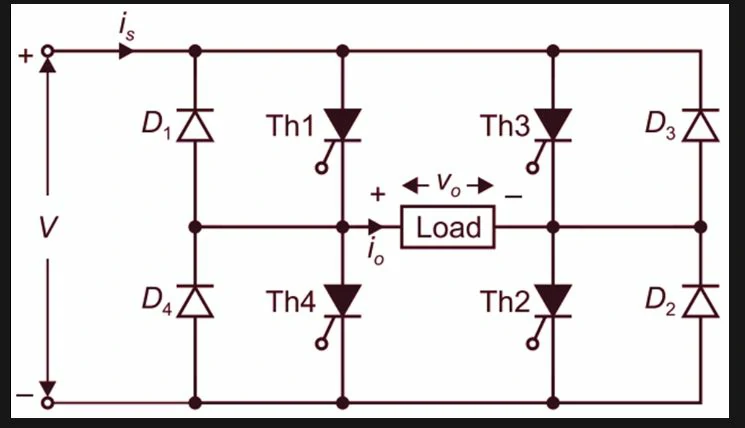

Figure 2 : Onduleur de puissanceUn onduleur de puissance est un appareil électronique qui convertit le courant continu (DC) d'une batterie ou d'une autre source d'énergie en courant alternatif (AC), qui est le type d'énergie utilisé dans la plupart des appareils électroménagers et électroniques. Il vous permet d'utiliser des appareils nécessitant du courant alternatif lorsque vous n'avez pas accès à une source de courant alternatif traditionnelle.2.1 Fonctionnement des onduleurs de puissance :

Un onduleur fonctionne en prenant l'alimentation en courant continu et en la faisant passer par des circuits électroniques qui la convertissent en courant alternatif. Le processus comprend plusieurs étapes, notamment la conversion du courant continu en courant alternatif, le filtrage pour lisser la forme d'onde et la régulation de la tension pour maintenir la stabilité de la sortie. Le courant alternatif produit par l'onduleur a généralement une fréquence de 50 ou 60 Hz, en fonction de la norme électrique de la région.

2.2 Utilisation de l'onduleur de puissance :

Pour utiliser un onduleur, il faut généralement le connecter à une source de courant continu telle qu'une batterie de voiture ou une batterie à décharge profonde séparée. L'onduleur est équipé de bornes d'entrée ou de câbles que vous connectez aux bornes positives et négatives de la batterie. Une fois la connexion effectuée, vous pouvez brancher vos appareils à courant alternatif dans les prises de courant alternatif de l'onduleur pour les alimenter.

Les onduleurs sont disponibles en différentes tailles et puissances, allant des petits onduleurs pouvant alimenter un ordinateur portable ou de petits appareils électroniques aux onduleurs plus grands capables de faire fonctionner des outils électriques, des appareils électroménagers ou même toute une maison pendant une panne de courant. La taille de l'onduleur dont vous avez besoin dépend de la puissance requise par les appareils que vous souhaitez alimenter. Vous devez tenir compte de la puissance en watts ou de la consommation de courant de vos appareils pour vous assurer que l'onduleur peut supporter la charge sans surchauffer ou déclencher ses circuits de protection.

2.3 Onduleur de voiture :

Il est important de noter que l'utilisation d'un onduleur avec une batterie de voiture pendant de longues périodes sans faire tourner le moteur peut épuiser la charge de la batterie. Il est recommandé de faire tourner le moteur périodiquement pour recharger la batterie ou d'utiliser une batterie à décharge profonde distincte, spécialement conçue pour alimenter les onduleurs.

Si les onduleurs sont généralement utilisés pour alimenter les appareils électroniques et électroménagers dans les voitures, les camions, les bateaux et les véhicules de loisirs, ils peuvent également être utilisés dans les systèmes d'alimentation solaire hors réseau, les installations d'alimentation de secours et d'autres applications où l'accès au courant alternatif conventionnel est limité ou indisponible.

Les onduleurs de voiture convertissent le courant continu de la batterie ou de l'allume-cigare de votre voiture en courant alternatif qui peut être utilisé pour alimenter les appareils électroniques. Voici comment ils fonctionnent généralement :

- Branchement : Pour utiliser un onduleur de voiture, il faut le brancher soit directement sur la batterie de la voiture, soit sur la prise d'accessoires de 12 V (prise de l'allume-cigare). Certains onduleurs sont équipés de câbles intégrés qui peuvent être branchés directement dans la prise, tandis que d'autres nécessitent que l'on connecte l'onduleur aux bornes de la batterie à l'aide de câbles appropriés.

- Conversion de courant continu en courant alternatif : Une fois connecté, l'onduleur prend le courant continu de 12 V du système électrique de la voiture et le convertit en courant alternatif de 120 V (ou une autre tension standard en fonction du modèle). Le courant continu passe par des circuits électroniques qui utilisent des transistors ou d'autres dispositifs semi-conducteurs pour activer et désactiver rapidement le courant continu, créant ainsi une forme d'onde de courant alternatif.

- Régulation de la forme d'onde : La forme d'onde de sortie CA produite par l'onduleur peut ne pas être une onde sinusoïdale parfaite, mais peut être une onde sinusoïdale modifiée ou une onde sinusoïdale pure, selon le modèle de l'onduleur. Les onduleurs à onde sinusoïdale modifiée se rapprochent d'une onde sinusoïdale, tandis que les onduleurs à onde sinusoïdale pure produisent une forme d'onde lisse et de haute qualité qui ressemble beaucoup à l'alimentation électrique.

- Régulation de la sortie : L'onduleur régule également la tension et la fréquence de sortie afin de garantir une alimentation stable aux appareils connectés. Cela permet de protéger les appareils des dommages potentiels dus aux fluctuations de la tension ou à une fréquence incohérente.

- Prise CA : L'onduleur est équipé d'une ou plusieurs prises de courant alternatif où vous pouvez brancher vos appareils électroniques. Ces prises fournissent un courant alternatif standard, ce qui vous permet d'alimenter des appareils tels que des ordinateurs portables, des smartphones, des ventilateurs portables et de petits appareils qui nécessitent une alimentation en courant alternatif.

- Capacité de l'onduleur : Les onduleurs de voiture sont disponibles en différentes puissances, allant des puissances les plus faibles, adaptées au chargement de petits appareils, aux puissances les plus élevées, capables d'alimenter des appareils plus importants. Il est important de choisir un onduleur d'une capacité suffisante pour répondre aux besoins en énergie des appareils que vous avez l'intention d'utiliser.

- Lorsque vous utilisez un onduleur dans une voiture, il est essentiel de tenir compte de la puissance absorbée et de la capacité de la batterie de votre voiture. Faire fonctionner des appareils de forte puissance pendant une période prolongée sans que le moteur tourne peut décharger la batterie. Il est recommandé de faire tourner le moteur périodiquement pour recharger la batterie ou d'envisager l'utilisation d'une batterie à décharge profonde spécialement conçue pour l'utilisation d'un onduleur.

2.4 Onduleur solaire :

Création d'un onduleur solaire a construction d'un onduleur à partir de zéro nécessite des connaissances approfondies en électronique et en électrotechnique. Il s'agit de concevoir et d'assembler des circuits et des composants complexes. En raison de la complexité et des considérations de sécurité qu'elle implique, cette activité n'est pas recommandée aux personnes qui n'ont pas d'expertise dans ce domaine.

Pour fabriquer un onduleur qui convertit 12V DC en 220V AC, vous aurez généralement besoin des composants et des étapes suivants :

Composants :

- Transistors de puissance ou MOSFETs

- Transformateur

- Condensateurs

- Diodes

- Résistances

- Circuit imprimé (PCB)

- Dissipateurs de chaleur

- Autres composants électroniques nécessaires

Les étapes :

- Concevoir le circuit : Il s'agit de sélectionner les composants appropriés et de concevoir le circuit du convertisseur de puissance. Cela nécessite une bonne compréhension de l'électronique de puissance et des principes de conception des circuits.

- Assembler le circuit : Une fois la conception du circuit terminée, vous devez assembler les composants sur une carte de circuit imprimé conformément au schéma du circuit. Veillez à respecter les consignes de sécurité appropriées et à utiliser des techniques d'isolation et de dissipation thermique adéquates.

- Connecter le transformateur : Connectez le transformateur au circuit. Le transformateur est chargé d'élever la tension de l'entrée CC à la tension de sortie CA souhaitée.

- Test et dépannage : Après avoir assemblé le circuit, testez-le pour vous assurer qu'il fonctionne correctement. Utilisez le matériel de test approprié et respectez les consignes de sécurité. Résolvez les problèmes qui peuvent survenir au cours des essais.

- Veuillez noter que la construction d'un onduleur à partir de zéro nécessite des connaissances et des compétences techniques avancées. Il est essentiel de donner la priorité à la sécurité, car travailler avec des tensions élevées peut être dangereux. Il est conseillé de consulter des ingénieurs électriciens professionnels ou des experts dans le domaine pour obtenir des conseils si vous avez l'intention de poursuivre un tel projet.

3. Différences fonctionnelles :

Les convertisseurs de fréquence se concentrent sur le contrôle précis de la vitesse et du couple du moteur, optimisant ainsi la consommation d'énergie et améliorant les performances globales. D'autre part, les convertisseurs de puissance excellent dans la conversion du courant continu en courant alternatif stable, ce qui permet d'utiliser des appareils alimentés en courant alternatif dans des environnements dotés de sources d'alimentation en courant continu. Alors que les convertisseurs de fréquence sont largement utilisés dans les environnements industriels, les convertisseurs de puissance sont indispensables pour diverses applications telles que l'alimentation de secours, les systèmes hors réseau et les solutions d'alimentation mobile.

4. Applications et industries :

Les convertisseurs de fréquence jouent un rôle essentiel dans diverses industries, notamment la fabrication, les systèmes de chauffage, de ventilation et de climatisation, les usines de traitement des eaux et les systèmes d'énergie renouvelable. Ces dispositifs améliorent le contrôle des processus, réduisent l'usure des équipements et contribuent à d'importantes économies d'énergie. Ils sont utilisés dans les pompes, les ventilateurs, les compresseurs, les convoyeurs et d'autres machines qui nécessitent un contrôle précis de la vitesse du moteur.

Les onduleurs de puissance trouvent des applications dans un large éventail de scénarios. Ils sont essentiels pour alimenter les appareils ménagers en cas de panne de courant, pour permettre l'approvisionnement en électricité dans les zones reculées et pour intégrer les sources d'énergie renouvelables dans les réseaux électriques existants. Les onduleurs de puissance sont couramment utilisés dans les systèmes d'alimentation solaire hors réseau, les maisons mobiles, les véhicules de loisirs et servent de solutions d'alimentation de secours fiables dans les situations d'urgence.

Conclusion:Il est essentiel de comprendre les différences entre les convertisseurs de puissance et les convertisseurs de fréquence pour prendre des décisions éclairées en matière de conversion de l'énergie électrique. En examinant attentivement leurs fonctionnalités, leurs applications et leurs avantages, vous pourrez sélectionner le dispositif idéal pour répondre à vos besoins spécifiques en matière de conversion d'énergie. Que vous ayez besoin d'un contrôle précis de la vitesse du moteur ou d'une conversion efficace du courant continu en courant alternatif, les convertisseurs de puissance et les convertisseurs de fréquence offrent des avantages distincts pour diverses industries et applications. Choisissez judicieusement et libérez le potentiel de la conversion de l'énergie électrique pour améliorer les performances, l'efficacité et la fiabilité.En ce qui concerne les autres questions, elles couvrent un large éventail de sujets liés aux convertisseurs de puissance. Si vous avez des questions spécifiques, n'hésitez pas à les poser et je serai heureux de vous aider !