Introducción

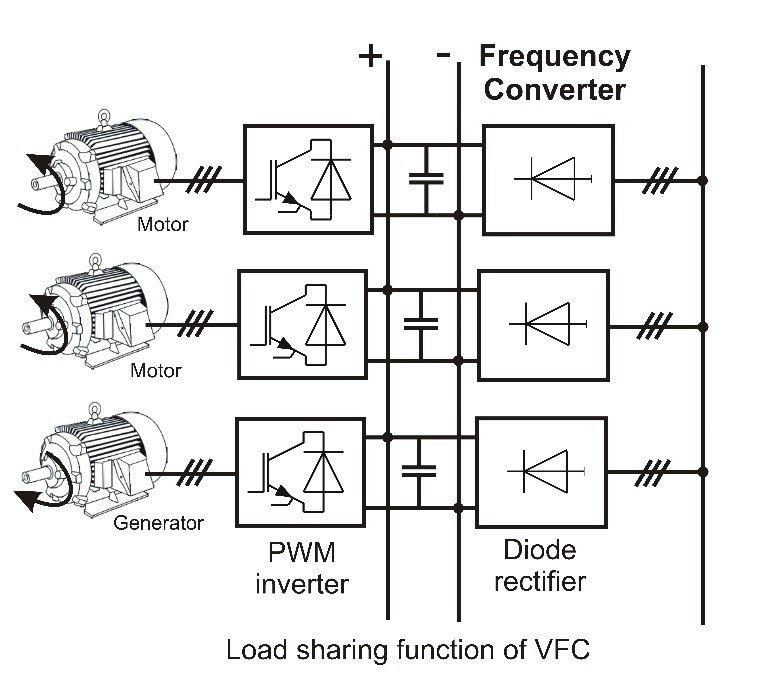

When discussing “increasing the capacity of the variable frequency drive,” we are referring to situations where the rated capacity of the variador de frecuencia (VFD) o convertidor de frecuencia is considered relative to the motor it controls. Normally, the capacity of the VFD matches the motor’s rated power, but certain conditions may necessitate choosing a higher-capacity VFD to ensure proper operation.So, in essence, increasing the capacity of the frequency converter is all about ensuring your motor gets the power it needs, precisely when it needs it. Below, we outline the main circumstances that require increasing the capacity of a variador de velocidad.

1. The Rated Current of the Inverter Is Too Low

In some cases, the inversor VFD‘s rated current may be lower than the rated current of the motor, even when the motor and VFD have the same capacity. If this occurs, it’s essential to assess the motor’s load and operating conditions. For motors operating under heavy loads, it may be necessary to select a variador de frecuencia with a higher capacity. This ensures the drive can handle the motor’s current demand without tripping or overheating, especially in high-load situations.

2. The Motor May Be Overloaded for a Short Time

A motor may experience short-term overloads, which are periods where the load exceeds its rated capacity. For example, heavy industrial machinery like mixers, crushers, or conveyor systems may face intermittent overloads. While the motor can tolerate short-term overloads for several minutes or even up to an hour, the convertidor de frecuencia typically only supports overloads of 150% for up to one minute. This discrepancy means that the variador de frecuencia has limited overload capacity compared to the motor. Therefore, if the motor is likely to operate under short-term overloads, increasing the capacity of the inversor VFD is necessary to prevent overload protection from activating prematurely.

3. Special Requirements for Acceleration and Deceleration Time

Acceleration and deceleration times are key factors in motor control, particularly for loads with large inertia. For example, starting and stopping times can vary based on the load’s inertia (GD²). If a motor must accelerate or decelerate quickly, the variador de frecuencia needs to supply enough power to handle the increased torque demands. If the variador de velocidad is undersized, it may struggle to meet the acceleration and deceleration requirements, resulting in performance issues. A larger-capacity convertidor de frecuencia is needed in the following situations:

- When fast start and stop cycles are required, such as in material handling or packaging systems.

- When the motor frequently operates in jog mode, requiring repeated starts and stops.

4. With Impact Load

Impact loads, such as those found in presses, punches, or systems using clutches, present unique challenges for motor control. In these applications, the motor may already be spinning when a clutch engages, causing a sudden load on the motor. When the clutch engages, the motor’s speed drops, increasing the slip and the motor’s current draw. This rapid change in current may trigger overcurrent protection in the inversor VFD. To prevent such interruptions, increasing the capacity of the variador de frecuencia ensures the system can handle these sudden impact loads without tripping or causing damage to the drive or motor.

Conclusión

In summary, there are several key circumstances where increasing the capacity of a variador de frecuencia is necessary. These include situations where the rated current of the VFD is too low, the motor faces short-term overloads, there are special requirements for fast acceleration or deceleration, or the system operates under impact loads. In each case, upgrading to a higher-capacity convertidor de frecuencia ensures that the motor and drive system operate reliably and efficiently, reducing the risk of operational disruptions.