When your solar system underperforms, the real culprit is often the solar combiner box—leading to energy loss, safety risks, and costly repairs. Learn how to detect and fix it.

Die Solarkombinationskasten, also known as a PV string combiner box, centralizes and protects your PV array wiring. Failure can stem from wiring faults, fuse issues, poor grounding, or even weather. Here’s how to troubleshoot and maintain it properly to keep your PV system operating safely and efficiently.

Before you replace parts or call a technician, explore this guide for deeper insights into PV combiner box reliability.

Why Does a Solar Combiner Box Stop Working?

Although PV combiner boxes are designed to protect and simplify solar wiring systems, they’re not immune to failure. These issues often go unnoticed until performance drops or faults appear in the system’s monitoring. Let’s explore what commonly leads to combiner box malfunctions.

First, poor installation or aging wiring inside the solar combiner can cause loose connections or insulation degradation. As a result, this leads to fluctuating voltage or current and potential fire hazards. Over time, high-temperature environments and lack of airflow can lead to overheating of components in the DC combiner box for solar setups.

Another common cause is breaker malfunction. If the circuit breakers within the PV-String-Kombinationskasten are undersized or faulty, they may trip frequently or fail to isolate faults properly, creating cascading problems for the inverter or battery system.

Environmental stress, including water ingress and dust accumulation, can cause corrosion or short circuits—especially if the enclosure lacks proper IP protection. Lightning surges may also disable the surge protection devices (SPDs) inside the combiner box PV units, further exposing the system to risk.

In short, even a minor flaw in the solar PV combiner box can disrupt the system’s integrity. That’s why regular inspection, quality components, and proper grounding are essential to ensuring stability.

Steps to Identify Common Solar Combiner Faults

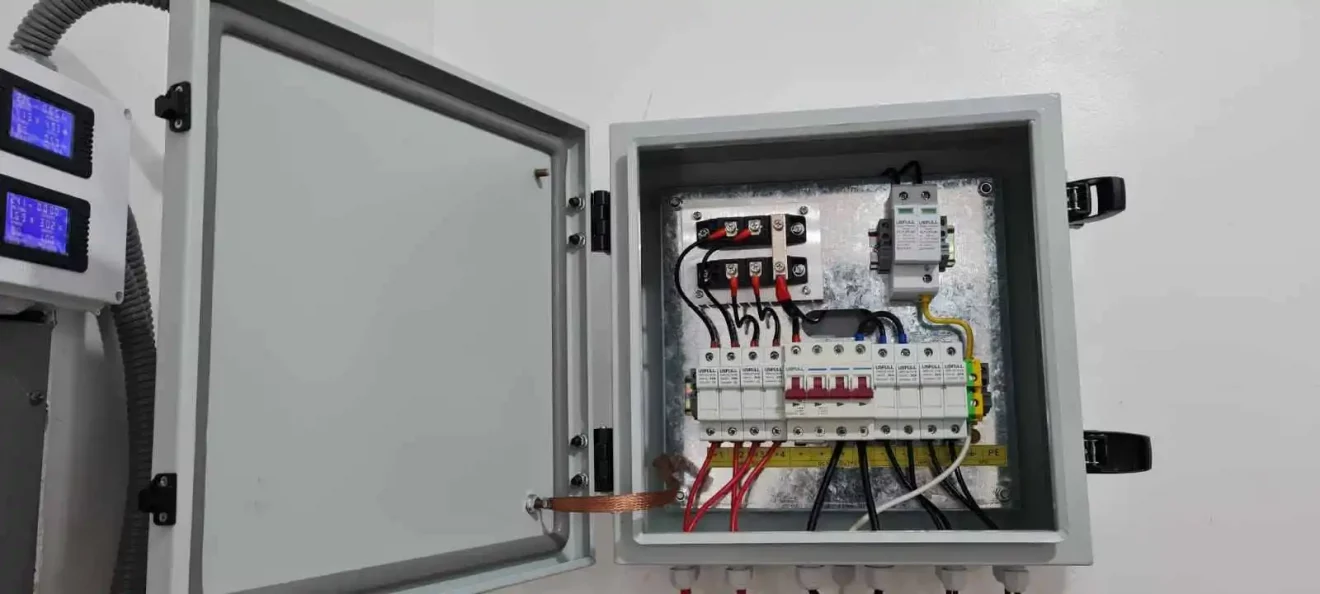

Effective troubleshooting starts with a structured approach. The first step is a visual inspection. Open the enclosure and check for burn marks, corrosion, water ingress, or visibly damaged wires. All connections inside the combiner box should be tight, clean, and secure.

Next, verify continuity and voltage readings on each string input. A digital multimeter or a CAT III 1500V-rated clamp meter is recommended for PV system testing. Compare each string’s output—uneven readings may signal poor connections, a blown fuse, or a module fault.

Prüfen Sie die fuse holders and test each fuse for continuity. Burned fuses might result from a ground fault, overcurrent, or surge. Be sure to switch off the DC breaker before doing any live testing or replacements.

If your PV string box is equipped with monitoring functions, review the data. Inconsistent readings or signal loss may point to a failed sensor, misconfigured communication address, or wiring interference.

Lastly, don’t forget to examine the grounding system. Loose or corroded grounding can introduce electrical shock hazards and damage the solar combiner. Using a multimeter, confirm the continuity of the ground loop and verify that all grounding connections comply with national standards.

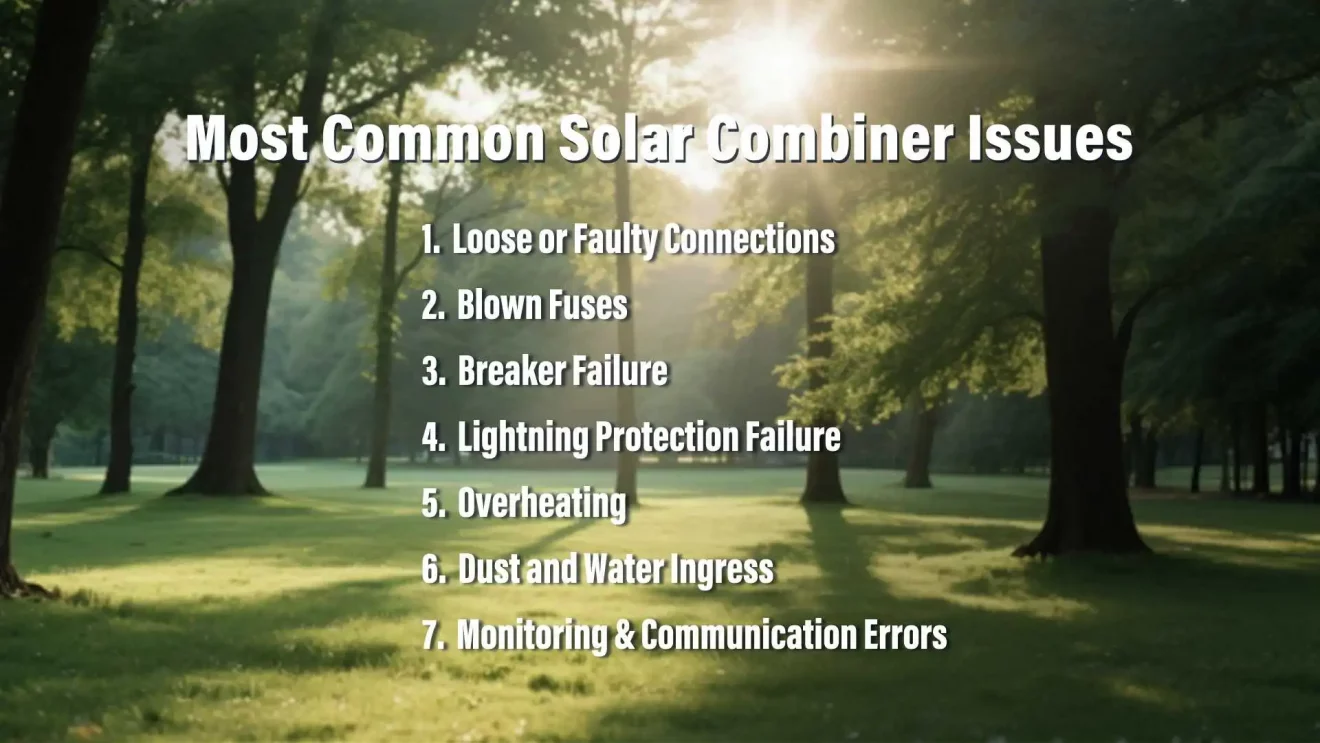

Most Common Solar Combiner Issues and How to Fix Them

Knowing what problems typically arise in a Verteilerkasten PV setup will help you resolve them quickly and efficiently.

1. Loose or Faulty Connections

Loose terminals can cause resistance, overheating, and eventual melting. Tighten all terminal blocks and retorque the connections during each inspection. Replace any oxidized or burnt terminals.

2. Blown Fuses

Fuses inside PV combiner boxes protect the system from overcurrent. If a fuse blows repeatedly, it could indicate a short circuit, undersized fuse, or fault in the solar module. Replace only with the correct type and rating.

3. Breaker Failure

DC circuit breakers may trip due to overloads or degrade from age and UV exposure. Replace faulty breakers and ensure your combiner box matches the system’s rated current and voltage.

4. Lightning Protection Failure

SPD devices inside PV string combiner boxes can absorb electrical surges from lightning. If they fail, the surge protector indicator will show “RED” or disconnected status. Replace immediately and verify earthing resistance is within limit.

5. Overheating

Combiner boxes installed in hot climates or direct sunlight can suffer from thermal degradation. Ensure ventilation is adequate, and consider using metal enclosures with better heat dissipation.

6. Dust and Water Ingress

IP65 or IP66-rated enclosures are recommended for outdoor environments. Regularly clean the PV box to prevent dust buildup, and reseal any broken gaskets to prevent water leakage.

7. Monitoring & Communication Errors

When the system is unresponsive, verify that the baud rate, communication address, and termination resistors are correctly configured. Faulty signal cables or incompatible software can also disrupt monitoring.

By resolving these issues promptly, you extend your PV system’s lifespan and prevent unexpected downtime.

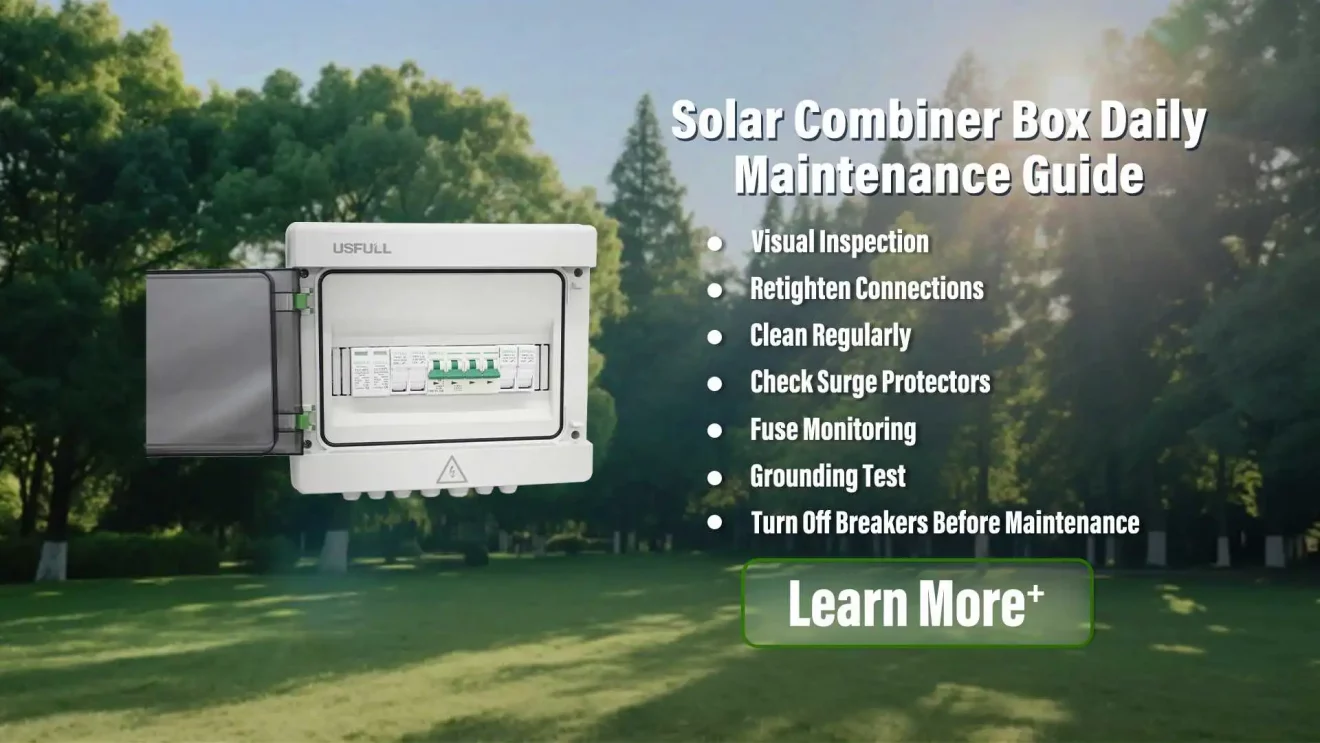

Solar-Kombinator-Box Daily Maintenance Guide

Routine maintenance of your PV string combiner box ensures consistent performance, protects against unexpected failures, and enhances system safety. Here’s a checklist for maintaining your solar combiner box:

Visuelle Inspektion: Check every quarter for discoloration, rust, or broken seals. Look for signs of overheating or burnt plastic near terminals.

Retighten Connections: Vibration and heat cycles can loosen screws over time. Use a torque screwdriver to check terminal blocks.

Regelmäßig reinigen: Remove dust, insects, and leaves from the enclosure and ensure ventilation holes aren’t blocked.

Check Surge Protectors: SPD status indicators must be inspected monthly. Replace immediately if damaged.

Fuse Monitoring: Never touch the fuse under load. Replace any blown fuse with the correct rating. Ensure all current values are zero before removal.

Grounding Test: Use a multimeter to confirm grounding continuity and resistance within safe limits.

Turn Off Breakers Before Maintenance: Always disconnect the DC circuit breaker and wear insulated PPE while performing service tasks.

These practices ensure your DC-Kombikasten für Solaranlagen applications remains stable, durable, and safe across all weather conditions.

A well-maintained solar PV-Kombinationskasten prevents downtime and keeps your PV system productive and safe.