Einführung

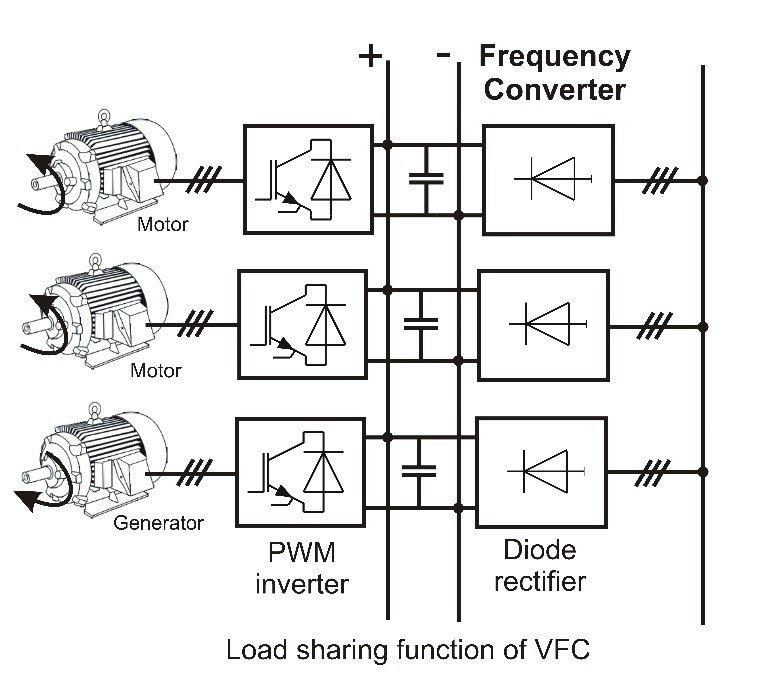

Wenn wir von "Erhöhung der Leistung des Frequenzumrichters" sprechen, beziehen wir uns auf Situationen, in denen die Nennleistung des Frequenzumrichters Antrieb mit variabler Frequenz (VFD) oder Frequenzumrichter wird im Verhältnis zu dem von ihm gesteuerten Motor betrachtet. Normalerweise entspricht die Leistung des Frequenzumrichters der Nennleistung des Motors, aber unter bestimmten Bedingungen kann es notwendig sein, einen Frequenzumrichter mit höherer Leistung zu wählen, um einen ordnungsgemäßen Betrieb zu gewährleisten. Im Folgenden beschreiben wir die wichtigsten Umstände, die eine Erhöhung der Kapazität eines Antrieb mit variabler Geschwindigkeit.

1. Der Nennstrom des Wechselrichters ist zu niedrig

In einigen Fällen ist die Wechselrichter VFDDer Nennstrom des VFD kann niedriger sein als der Nennstrom des Motors, auch wenn Motor und VFD die gleiche Leistung haben. In diesem Fall ist es wichtig, die Last und die Betriebsbedingungen des Motors zu beurteilen. Bei Motoren, die unter hoher Last betrieben werden, kann es erforderlich sein, einen variabler Frequenzumrichter mit einer höheren Kapazität. Dadurch wird sichergestellt, dass der Umrichter den Strombedarf des Motors bewältigen kann, ohne auszulösen oder zu überhitzen, insbesondere in Situationen mit hoher Last.

2. Der Motor kann kurzzeitig überlastet sein

Bei einem Motor kann es zu kurzzeitigen Überlastungen kommen, d. h. zu Zeiträumen, in denen die Last seine Nennkapazität überschreitet. Zum Beispiel können schwere Industriemaschinen wie Mischer, Brecher oder Fördersysteme zeitweise überlastet werden. Während der Motor kurzfristige Überlastungen für einige Minuten oder sogar bis zu einer Stunde tolerieren kann, ist die Frequenzumrichter unterstützt in der Regel nur Überlastungen von 150% für bis zu einer Minute. Diese Diskrepanz bedeutet, dass die variabler Frequenzantrieb hat im Vergleich zum Motor eine begrenzte Überlastfähigkeit. Wenn der Motor wahrscheinlich unter kurzzeitiger Überlast betrieben wird, sollte daher die Kapazität des Wechselrichter VFD ist notwendig, um ein vorzeitiges Auslösen des Überlastungsschutzes zu verhindern.

3. Besondere Anforderungen an die Beschleunigungs- und Verzögerungszeit

Beschleunigungs- und Verzögerungszeiten sind Schlüsselfaktoren bei der Motorsteuerung, insbesondere bei Lasten mit großer Trägheit. So können beispielsweise die Start- und Stoppzeiten je nach Trägheit der Last (GD²) variieren. Wenn ein Motor schnell beschleunigen oder abbremsen muss, ist die variabler Frequenzantrieb muss genügend Leistung liefern, um den erhöhten Drehmomentbedarf zu decken. Wenn die Antrieb mit variabler Geschwindigkeit unterdimensioniert ist, kann es Schwierigkeiten haben, die Beschleunigungs- und Abbremsanforderungen zu erfüllen, was zu Leistungsproblemen führt. Ein größeres Fassungsvermögen Frequenzumrichter ist in den folgenden Situationen erforderlich:

- Wenn schnelle Start- und Stoppzyklen erforderlich sind, wie z. B. bei Materialtransport- oder Verpackungsanlagen.

- Wenn der Motor häufig im Tippbetrieb läuft und wiederholt gestartet und gestoppt werden muss.

4. Mit Stoßbelastung

Stoßbelastungen, wie sie in Pressen, Stanzen oder Systemen mit Kupplungen auftreten, stellen besondere Anforderungen an die Motorsteuerung. Bei diesen Anwendungen kann sich der Motor bereits drehen, wenn eine Kupplung einrastet, was eine plötzliche Belastung des Motors verursacht. Wenn die Kupplung einrastet, sinkt die Motordrehzahl, was den Schlupf und die Stromaufnahme des Motors erhöht. Diese schnelle Stromänderung kann den Überstromschutz im Wechselrichter VFD. Um solche Unterbrechungen zu vermeiden, sollte die Kapazität des variabler Frequenzantrieb stellt sicher, dass das System diese plötzlichen Stoßbelastungen bewältigen kann, ohne auszulösen oder den Antrieb oder Motor zu beschädigen.

Schlussfolgerung

Zusammenfassend lässt sich sagen, dass es mehrere wichtige Umstände gibt, unter denen eine Erhöhung der Kapazität eines variabler Frequenzumrichter erforderlich ist. Dazu gehören Situationen, in denen der Nennstrom des Frequenzumrichters zu niedrig ist, der Motor kurzzeitig überlastet wird, besondere Anforderungen an eine schnelle Beschleunigung oder Verzögerung bestehen oder das System unter Stoßbelastungen arbeitet. In jedem Fall ist die Aufrüstung auf einen leistungsfähigeren Frequenzumrichter stellt sicher, dass der Motor und das Antriebssystem zuverlässig und effizient arbeiten, wodurch das Risiko von Betriebsunterbrechungen verringert wird.