Introduction

USFULL recently completed a successful project in Ho Chi Minh City, Vietnam, supplying high-performance frequency inverters for a vehicle brake testing system. The project’s focus was to enhance the precision and efficiency of brake testing for cars using the latest variable frequency drive (VFD) technology. The installation featured advanced solutions, showcasing the reliability and robustness of USFULL’s VFDs in demanding applications like automotive testing.

Vietnam’s Frequency Inverter Market Analysis

Vietnam’s market for frequency inverters has been growing rapidly, driven by increasing industrialization and automation. In particular, the demand for variable frequency inverters in sectors such as manufacturing, automotive, and heavy industries has surged. USFULL’s variable speed drive solutions offer significant advantages in this market. The company’s VFDs are known for their energy-saving capabilities, improved motor control, and ease of integration, all of which are key to meeting local demand for efficient and cost-effective technologies. By providing advanced VFD solutions, USFULL helps Vietnamese businesses reduce energy consumption, improve productivity, and extend the lifespan of critical machinery.

Project Details

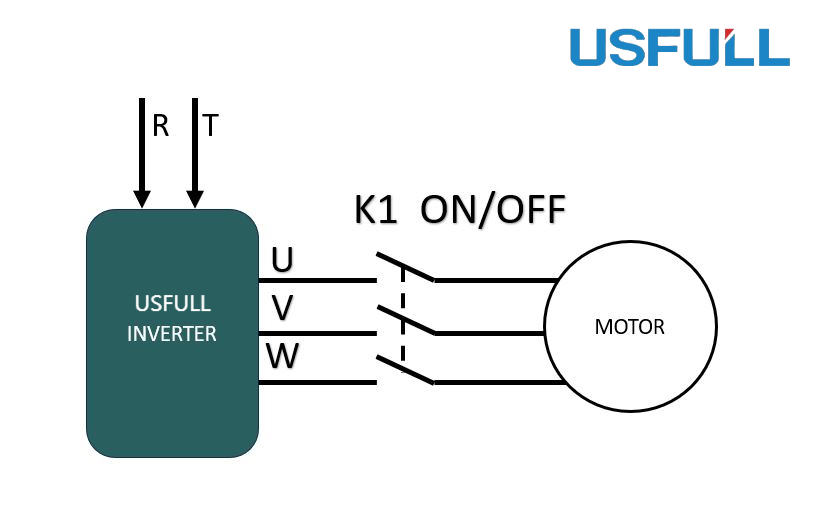

The core component of the project was a brake tester for cars, specifically designed to test the efficiency and performance of vehicle braking systems. The frequency inverter used in this system was a 5.5kW, single-phase 220V input and three-phase 220V output variable frequency inverter. This configuration powered a 2.2kW three-phase 220V motor. To ensure smooth operation, the VFD was integrated with a remote control system. Through this remote control, operators could easily open or close the soft starter, which connects the inverter VFD to the motor, ensuring the contactors inside the soft starter would disengage or engage as needed.

One of the key settings on the VFD was the free stop mode, configured under P6-10: 1 Coast to stop. This setting allowed for the VFD to stop the motor smoothly and safely without applying sudden braking, which is crucial for accurate brake testing results.

Technical Solution: USFULL VFD for Vehicle Brake Testing Equipment

USFULL’s FU9000D general type VFD was selected for this project due to its versatility, user-friendliness, and easy maintenance features. This variable frequency drive offers a comprehensive solution for controlling motor speed, ensuring stable voltage, and providing energy-saving options. In this brake testing system, the FU9000D helped improve the torque output and overall motor performance, critical for accurate brake diagnostics. Additionally, the drive’s ability to provide traverse control and motor protection ensured that the entire brake testing operation was efficient and reliable.

By leveraging USFULL’s advanced VFD technology, the brake testing system not only improved the precision of vehicle diagnostics but also reduced the system’s energy consumption. This combination of energy savings and high performance highlights the benefits that variable speed drives bring to automotive testing applications in Vietnam.

Conclusion

USFULL’s project in Ho Chi Minh City demonstrates the power and flexibility of their frequency inverters in real-world applications. With the growing demand for automated solutions in Vietnam, USFULL’s VFDs are set to become a key technology in various industries. The successful deployment in the vehicle brake testing system shows how variable frequency drives can improve operational efficiency, reduce costs, and enhance equipment longevity.